LCQ Series Wireless Remote Ultrasonic Gas Meter with LoRaWAN/NB

WUHAN TIMEWAVE IOT TECHNOLOGY CO.,LTD

| Model | Aluminum alloy shell | On-off | NB-IoT | LoRaWAN |

| Functional version | G | K | NB+Operator | LR+frequency band |

| LCQ Series Wireless Remote Ultrasonic Gas Meter | . | . | . | . |

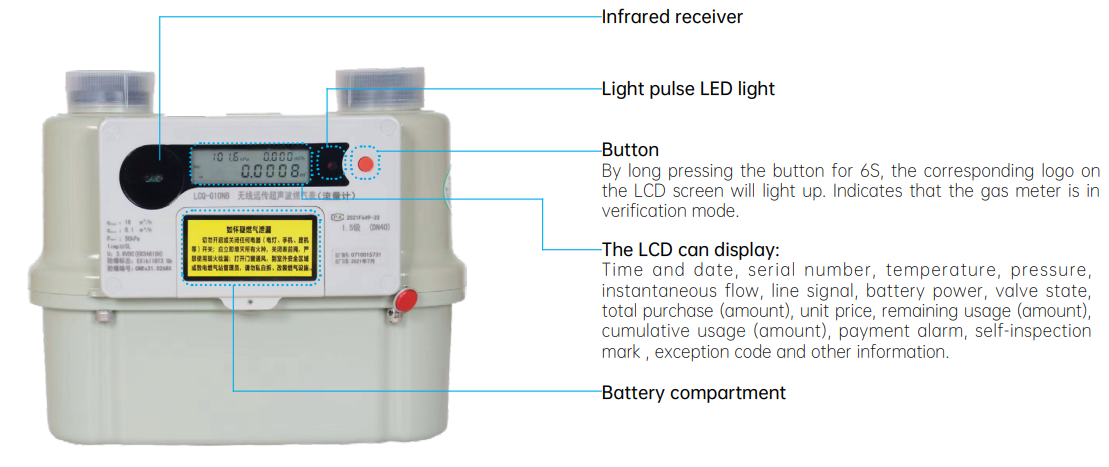

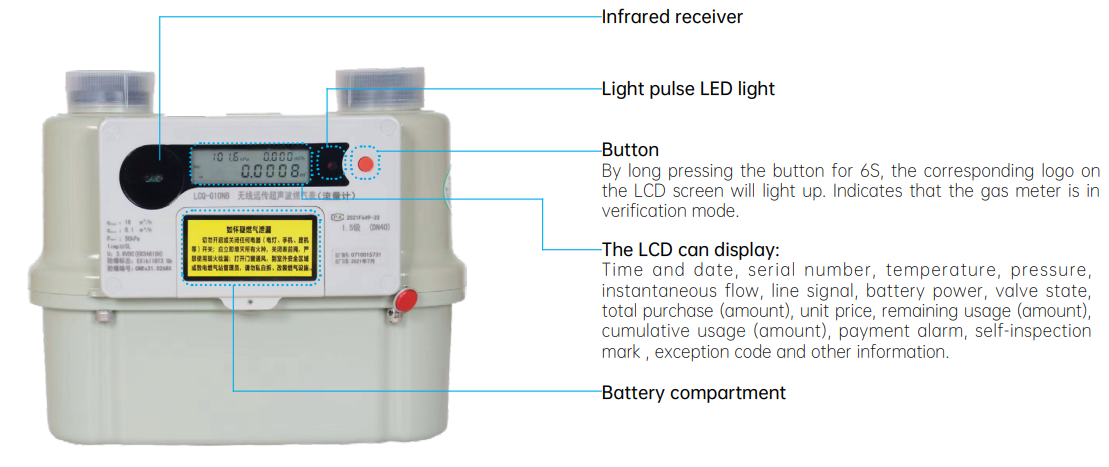

LCQ series wireless remote ultrasonic gas meter (hereinafter

referred to as gas meter) is an ultrasonic gas meter carefully

crafted by our company.High-precision ultrasonic transducers and

advanced software algorithms are used to achieve accurate

measurement, and combined with NB-IoT narrowband IoT communication

technology to realize the gas meter networking function.It meets

the requirements of GB/T39841-2021 "Ultrasonic Gas Meter",

JJG10302007 "Ultrasonic Flow Meter".It has measurement

characteristics such as high precision, strong reliability, wide

range ratio, and good durability. It also has intelligent functions

such as temperature and pressure correction, online monitoring,

meter reading, payment, and price adjustment. The gas meter is

suitable for measuring various non-corrosive gases. It can be

widely used in gas metering of gas users. It is a new generation of

ideal intelligent gas meter that effectively solves the measurement

loss caused by the fact that the range cannot meet the actual needs

and the temperature and pressure changes.

1. The gas meter has high measurement accuracy, adopts segmented flow

coefficient correction, low initial flow rate, and wide measuring

range;

2. Electronic metering, no moving parts, no mechanical loss, good

durability, long service life and low failure rate;

3. It has the characteristics of anti-noise, anti-electromagnetic

ffeld interference, anti-disassembly, and anti-reverse

installation;

4. It has alarm and cut-off functions such as micro-leakage, abnormal

flow, abnormal high temperature, unauthorized meter removal,

constant ffow, etc;

5. Adopt dual power supply design;

6. Encryption algorithm is used for remote communication data to

ensure data security;

7. The gas meter has built-in temperature and pressure sensors, which

can realize volume measurement under working conditions and

standard conditions;

8. The unique rectiffcation structure can better improve the

disturbance of the ffow ffeld;

9. Both the metering and main control modules are designed

independently, without mutual interference and good reliability;

10. Strong media adaptability, automatic correction

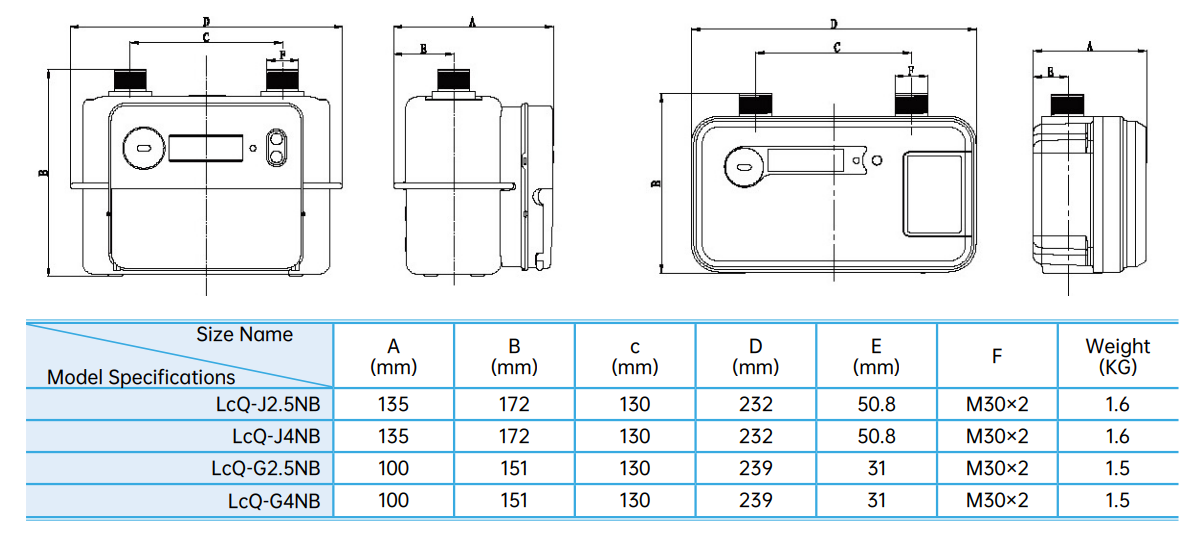

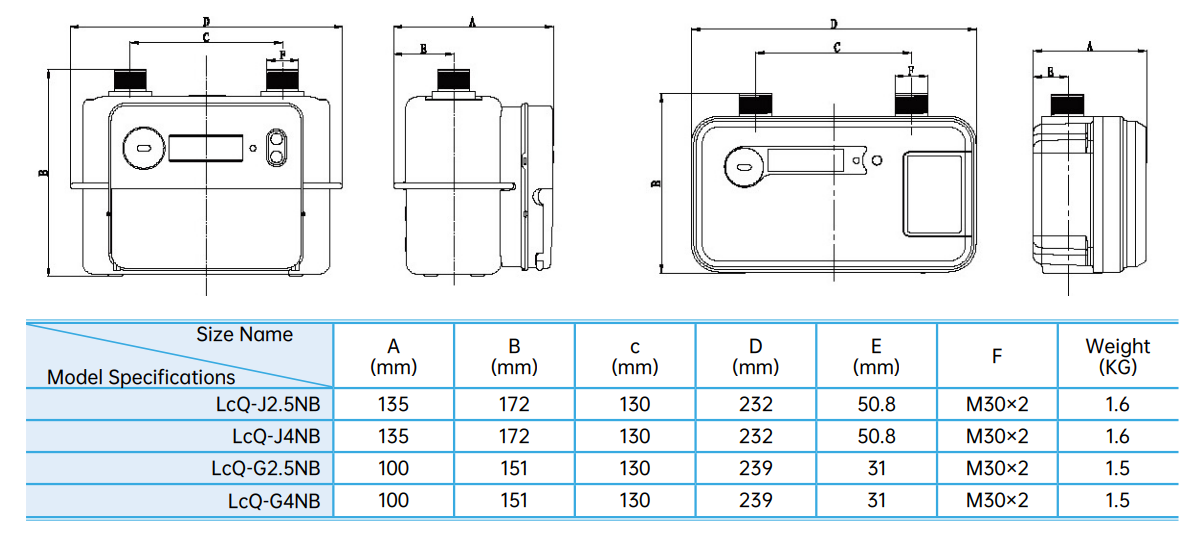

| Parameter Name | LCQ-J2.5NB(iron shell) | LCQ-G2.5NB(aluminum shell) | LCQ-J4NB | LCQ-G4NB |

| Maximum flow(m³/h ) | 4 | 6 |

| Minimum flow(m³/h ) | 0.025 | 0.04 |

| Thread of inlet and outlet pipes | M30×2 |

| Maximum pressure loss (Pa ) | 3250 |

| Center distance between inlet and outlet pipes (mm) | 130 |

| Valve | Built-in valve |

| Light pulse volume equivalent (L/pul ) | 2 |

| Maximum working pressure (kPa) | ≤50 |

| Meter tightness | No leakage for 3 minutes under 1.5 times the maximum working

pressure |

| Power supply method | ER34615H/3.6V |

| Accuracy level | 1.5 Level |

| Indication error | qmin≤q≤q≤qmax±1.5% |

| Operating temperature | -10℃ ~40℃ |

| Storage temperature | -20℃ ~60℃ |

| Explosion Proof | ExibIIBT3 Gb |

| IP Grade | IP54 |

| Communication network | NB-IoT/LoRaWAN/CAT.1(Choose any one) |